The coming niches for UK design

First published by Blueprint, May 2015

First published by Blueprint, May 2015Where could the UK economy go next? Manufacturing accounts for 70 per cent of UK R&D, and large foreign firms take 54 per cent of it. Still, UK R&D spending as a percentage of GDP is well below that of German, Scandinavian, American, Japanese or Korean efforts. Ironically, though, today’s foreign-owned makers of cars, trains and other goods look more innovative than for many years. And three important new niches have emerged, beyond the purely digital arena, where designers and architects might usefully strut their stuff.

NICHE 1: Civilian drones, satellites and structural electronics In the military arena, BAe Systems makes Taranis unmanned combat aircraft demonstrators. They are based on 1.5m hours of work among 250 UK firms, including QinetiQ, GE Aviation and Rolls-Royce. Worrisome; but civilian companies such as Vulcan UAV could also have success, in sectors such as construction and agriculture.

In space satellites, the government hopes to raise Britain’s share of the world market from six to 10 per cent – £40 billion – by 2030. Plenty of work for the designers of ingenious experiments here.

In electronics, look out for the structural sort – systems that, directly integrated into aircraft and the like, can bear loads, save weight, or be made to form clever kinds of skins. Imperial College, for instance, has teamed up with Volvo in the fast-growing field, building a supercapacitor-based battery into the lid of a boot.

NICHE 2: Exploiting carbon and other materials Speak it softly, but the UK is well placed to put carbon to work. Far from being ‘dirty’, this element can be manipulated to offer product designers new capabilities.

Take Cambridge Nanosystems, a UK-based spinout from Cambridge University. Backed by a £500,000 Technology Strategy Board grant, it wants to make five tonnes a year of one-Carbon-atom-thick graphene in an ultra-pure state. It intends to use a patented plasma chemistry system to crack the methane emitted from landfill sites. Then the company hopes to develop applications of its graphene – including, perhaps, 1mm-thick indoor radiators warmed by electric current and painted on to walls.

Carbon isn’t the only material that will change the face of British design. The Conservative-LibDem Coalition put £235m into funding the new Sir Henry Royce Institute for Advanced Materials Research and Innovation. In time, we can expect designers to realise some dramatic spinoff from the Institute’s enquiries.

NICHE 3: Oil and gas systems The engineering skills built up around Britain’s base in hydrocarbons are not going to go away, even with a spell of low oil prices.

Begin with pumps and valves. Here, Weir Group applies its proprietary models in computational fluid dynamics to improve the products it supplies not just to the world’s oil and gas producers, but also to power stations, refineries, process plants and miners. Will designers of hydraulic engineering systems benefit from the exploitation of shale gas and oil in Britain? That depends on whether the new government allows horizontal drilling to go ahead.

Then there are the manufacturers that are orientated to the UK’s £9bn sector that deals with subsea oil and gas, and Newcastle-based Soil Machine Dynamics makes remote operating vehicles. SMD’s QTrencher 1000, for instance, uses high flow and high-pressure jetting to lay cables and small diameter pipes up to 3m beneath the seabed. We can expect more of Britain’s designers to gather round the interfaces for such Remote Operated Vehicles.

Finally, diesel generators are ripe for attack by designers. Their contribution to the nation’s CO2 and to its particulates is relatively small; their contribution to keeping hospital surgeries and City dealing rooms functioning when the National Grid or local power supplies fail is disproportionately large. The interfaces on these increasingly sophisticated systems? Still a long way from the 21st century.

Some designers may want Britain’s new government to revive UK manufacturing through the programme recommended by Mariana Mazzucato and Will Hutton – through a bold, patient, profitmaking and entrepreneurial state industrial policy, devoted above all to the green technologies pioneered by Germany. But given the travails of German energy policy, I’m not persuaded of the merits of this statist, top-down approach. Nor, on the other hand, would I leave design-led manufacturing innovation simply to market forces.

What to do? Well, at least extend the reach of design to the new niches described above. That will put us in a stronger position to influence policy and practice.

@jameswoudhuysen I use my bicycle every day. Exercise and access to shopping without any parking meters and all that fuzz. But alfa-cyclists are the worst. They are competing at 40 mph and always acting rudely to get where they are going.

A PRO-CAR CYCLIST WRITES: 12-1pm tomorrow on #R4, will be talking bikes, cars, pedestrians, public transport – and #JeremyVine

Stimulating piece on the #CrisisOfCustomerService by clever @ClaerB @FT.

All that Clinton-era #CustomerExperience guff was always for the birds - certainly compared with, er, price.

The new thang? Often there is NO service - and thus no #CX!

Articles grouped by Tag

Bookmarks

Innovators I like

Robert Furchgott – discovered that nitric oxide transmits signals within the human body

Barry Marshall – showed that the bacterium Helicobacter pylori is the cause of most peptic ulcers, reversing decades of medical doctrine holding that ulcers were caused by stress, spicy foods, and too much acid

N Joseph Woodland – co-inventor of the barcode

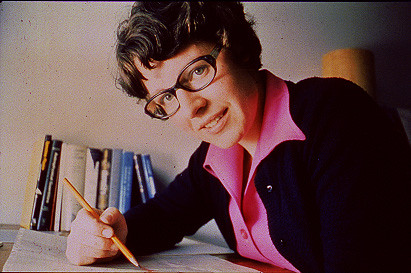

Jocelyn Bell Burnell – she discovered the first radio pulsars

John Tyndall – the man who worked out why the sky was blue

Rosalind Franklin co-discovered the structure of DNA, with Crick and Watson

Rosalyn Sussman Yallow – development of radioimmunoassay (RIA), a method of quantifying minute amounts of biological substances in the body

Jonas Salk – discovery and development of the first successful polio vaccine

John Waterlow – discovered that lack of body potassium causes altitude sickness. First experiment: on himself

Werner Forssmann – the first man to insert a catheter into a human heart: his own

Bruce Bayer – scientist with Kodak whose invention of a colour filter array enabled digital imaging sensors to capture colour

Yuri Gagarin – first man in space. My piece of fandom: http://www.spiked-online.com/newsite/article/10421

Sir Godfrey Hounsfield – inventor, with Robert Ledley, of the CAT scanner

Martin Cooper – inventor of the mobile phone

George Devol – 'father of robotics’ who helped to revolutionise carmaking

Thomas Tuohy – Windscale manager who doused the flames of the 1957 fire

Eugene Polley – TV remote controls

0 comments